Access the technical area to download the new catalogs click here

Sector of

Applications

Textile Machines

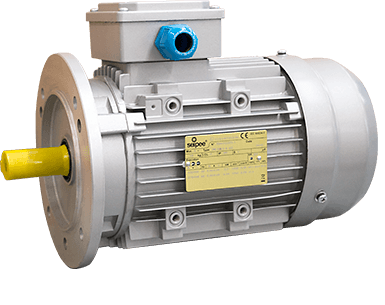

In our workshop we produce three-phase asynchronous motors ATEX

area for 22 – area for 2 3G/3D.

SEIPEE also designs and manufactures customized – electrically and mechanically – motors to meet the most diverse special needs of customers’ applications, with quick lead times, fast shipping and post-sales service always available. Every SEIPEE worker, employee, engineer or manager does not limit himself to only creating or selling a product, but personally contributes to form the “added value” that differentiates us from the competition and which is the true soul of our company.

The term ATEX (explosive atmosphere) indicates a mixture that, in particular conditions of temperature, pressure, air and fuel is able to originate an explosion. The fuel can be gas or dust.

The explosion-proof electric motors, often called more simply ATX engines, are used where safety against fire and explosions caused by gas, dust and liquids must be guaranteed. the term ATEX engine is the name of two European directives that regulate explosive atmospheres.

ATEX engines are suitable for installation in the following areas:

II 3G- EX nA II C T4 Gc

II 3D- EX tc III C T135°C Dc IP 65

II 3G- EX nA II C T3 Gc

The first step in choosing the engine is to correctly determine the hazardous area. When an electric motor must be installed in a place where the presence of hazardous materials is likely, it is the responsibility of the end user to correctly determine the appropriate class, category and group.

| GAS | DUST | CATEGORY | PROTECTION LEVEL | DESCRIPTION |

|---|---|---|---|---|

| 0 | 20 | 1 | Very high | Presence of continuous explosive atmosphere or for long periods |

| 1 | 21 | 2 | High | Presence of continuous explosive atmosphere or for long periods |

| 2 | 22 | 3 | Normal | Low probability of presence of explosive atmosphere and for short periods |

ATEX distinguishes four gas groups, based on how easily they are flammable (from a flame or a spark; not via self-ignition).

Group I (mines) there is only one gas group, ie methane.

Group II and divided into IIA, IIB, IIC. IIB certified electrical devices can be used in applications that require IIA group devices.

IIC certified electrical appliances can be used in applications requiring IIA and IIB units

| GAS GROUP | COMMON GAS |

|---|---|

| I (Mines) | Methane |

| IIA | Propane, ethanol, ammonia, butane … |

| IIB | Ethylene, hydrogen sulfide … |

| IIC | Hydrogen, acetylene … |

Among the most common applications are the processing of wheat, coal, sugar, wood and some chemicals such as sulfur.

IEC 60079-0 defines the new group of atmospheres III for powders (e.g. ATEX group II).

There are three “dust groups” defined by the properties of the powder:

| DUST GROUP | TYPE | FEATURES |

|---|---|---|

| IIA | Volatile substances fuels (fibers) | The finely divided solid particles, of dimensions equal to or less than 500 μm, which can be suspended in the air, they can be deposited outside the atmosphere under their own weight, they can burn or emit air and can form explosive mixtures with air at atmospheric and normal pressure temperatures. |

| IIIB | Non-conductive powders | Conductive powders with electrical resistivity greater than 103 Ω.m |

| IIIC | Ethylene, hydrogen sulfide | Conductive powders with an electrical resistivity equal to or less than 103 Ω.m |

Textile Machines

Wood Processing

Food & Beverage

Motion Control

Waste Treatment Plants

Labeling Machines

Copyright © 2019 SEIPEE S.p.A.MOTORI ELETTRICI | ELECTRIC MOTORS - Telefono:+39 059 850108 | Via S. Ferrari 4 Campogalliano , MODENA - 41011 | Registered Office: Viottolo Croce 1, 41011 Campogalliano (MO) | Operational headquarters: Via S. Ferrari 4, 41011 Campogalliano (MO) | Capitale Sociale € 120.000,00 i.v. - Codice Fiscale e P.IVA 00185010360 Iscr.Reg.Imp.Mo – R.E.A. n°152011.

All right reserved.

Privacy & Cookie Policy/ Social Media Policy

Directive 2009/125/EC of the European Community for the protection of the environment