Access the technical area to download the new catalogs click here

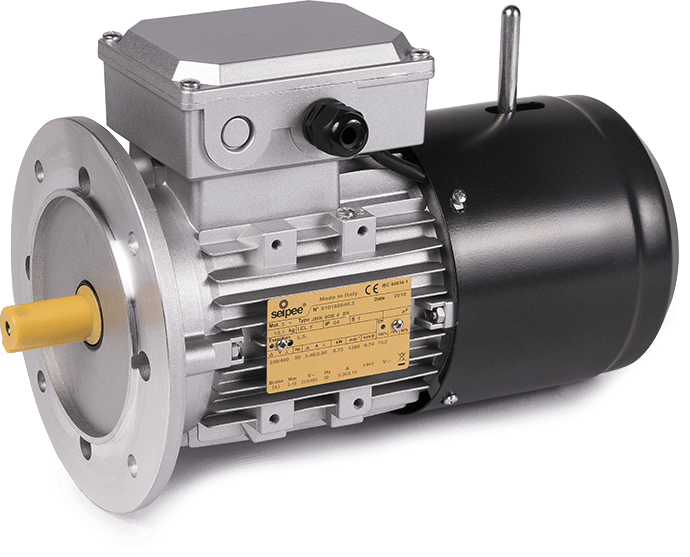

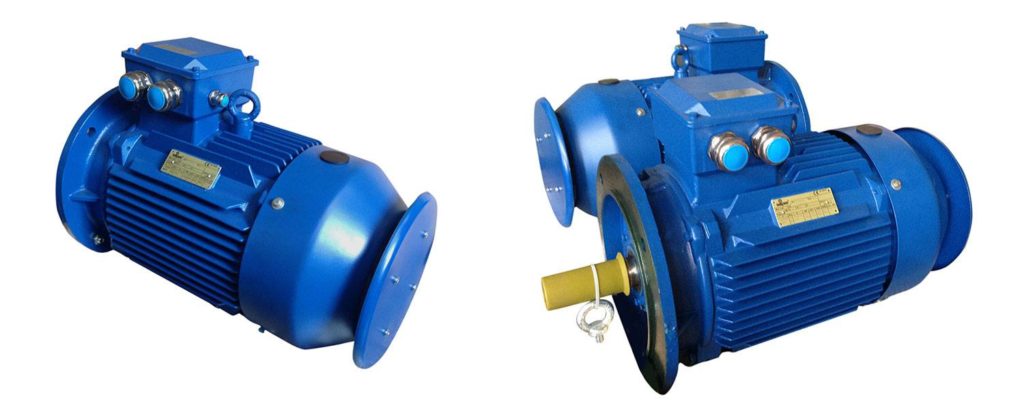

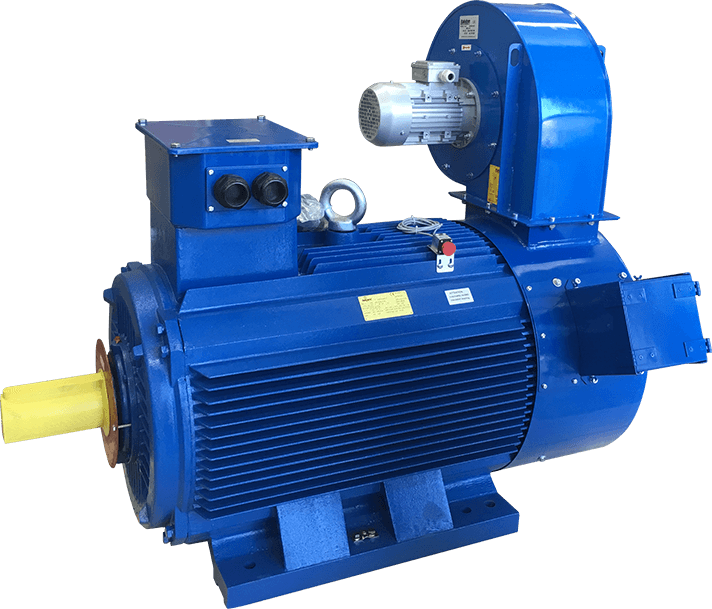

Copyright © 2019 SEIPEE S.p.A.MOTORI ELETTRICI | ELECTRIC MOTORS - Telefono:+39 059 850108 | Via S. Ferrari 4 Campogalliano , MODENA - 41011 | Registered Office: Viottolo Croce 1, 41011 Campogalliano (MO) | Operational headquarters: Via S. Ferrari 4, 41011 Campogalliano (MO) | Capitale Sociale € 120.000,00 i.v. - Codice Fiscale e P.IVA 00185010360 Iscr.Reg.Imp.Mo – R.E.A. n°152011.

All right reserved.

Privacy & Cookie Policy/ Social Media Policy