In a context where efficiency, performance, and adaptability are strategic requirements, the ability to design and produce customized electric motors represents a concrete competitive advantage for many industrial realities

From Mass Production to "Value" Production: The Paradigm Shift

During the 20th century, the manufacturing industry adopted production logics oriented towards standardization, high volume production, and reduction of unit costs.

However, technological evolution and increasing application complexity have pushed companies to reconsider their approach.

Today, we talk about the "lot one" production paradigm: the ability to produce each single piece custom-made, even in small volumes, without losing efficiency.

This has led to a substantial change, where value lies not only in the product but in the ability to perfectly adapt it to the customer’s needs.

In the electric motor sector, customization is not limited to aesthetic or superficial adaptation.

It is about functional customization: power, dimensions, mounting system, environmental resistances, IP protection class, insulation class, international standards, and even integration with sensors or digital interfaces.

This allows for the creation of motors perfectly aligned with the mechanical and environmental needs of the end customer, reducing downstream adaptation costs and improving the overall system efficiency.

Choosing a customized electric motor means: higher energy efficiency, smaller footprint, faster installation times, reduction of assembly errors, better integration with existing systems.

But it also means investing in a technical partnership, where the supplier becomes an integral part of the customer's engineering process.

This generates shared value and customer loyalty.

Companies that adopt custom solutions today are more resilient and ready to respond to highly fragmented and evolving markets.

Customized Design According to Seipee

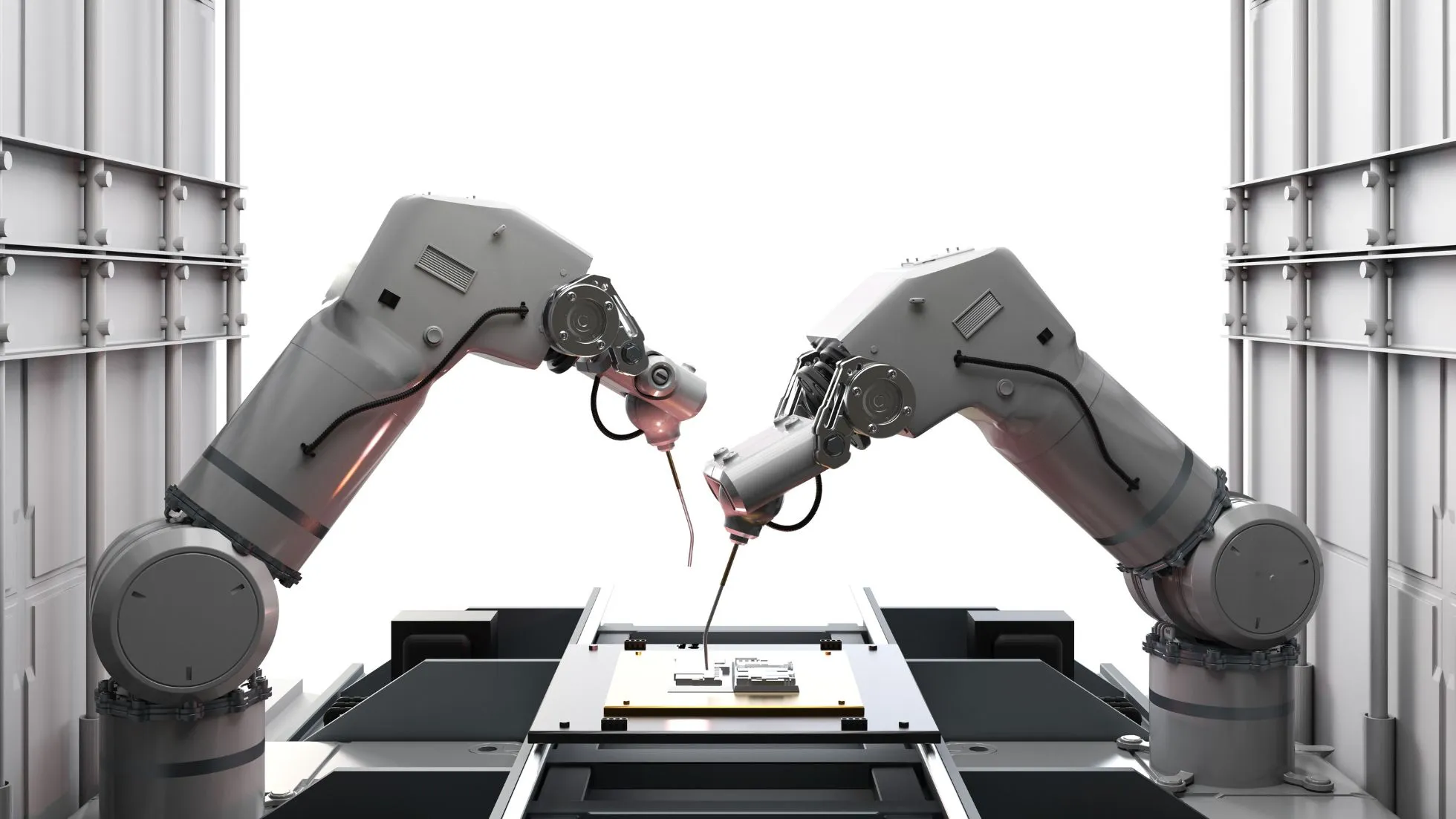

Seipee has developed a highly structured technical process for managing custom projects: from collecting technical requirements to analyzing usage conditions, to 3D design, testing, and industrialization.

The technical team works in co-design with the client, often interfacing directly with the customer’s R&D or technical office.

The goal is to create a motor that precisely meets the requested specifications, reducing compromises and increasing overall application performance.

Customization is particularly appreciated in highly technical sectors such as industrial automation, packaging, food & beverage, dosing systems, lifting, ventilation, plastic extrusion, and many other niches.

A concrete example is the design of low-profile motors for compact packaging lines, or high-resistance motors for ATEX environments or those exposed to humidity, dust, or intensive washing.

The ability to modulate performance based on the environment and machinery is a key success factor.

Contrary to popular belief, customization does not necessarily imply a significant increase in costs.

Thanks to experience and managed volumes, Seipee can optimize production even for special motors, with reduced production cycles and contained costs.

Moreover, the ROI for the customer is clear: reduced downtime, lower maintenance costs, superior energy efficiency, and in many cases, tax incentives related to innovation.

Customization, if well planned, is a sustainable and strategic investment.

Customization as a Lever for Industry 5.0

Industry 5.0 requires intelligent, interoperable components integrable into digital architectures.

Customization allows a motor to adapt not only to mechanical specifications but also to digital ones: encoders, sensors, predictive monitoring systems, IIoT connectivity, compatibility with industrial protocols (Modbus, Profinet, CANopen, etc.).

Seipee develops solutions designed to communicate with the factory ecosystem and integrate into smart manufacturing logics.

Custom-designed motors mean less waste, less oversizing, and better use of resources.

This translates into lower energy consumption, longer life, reduced environmental impact, and optimized recycling possibilities.

Moreover, customers can request materials or technical solutions with reduced environmental impact, aligned with their ESG policies.

Customization is therefore a fundamental piece in the transition toward a more sustainable industry.

The future of customization goes through intelligent configurators, AI applied to design, additive manufacturing for rapid prototyping, and digital technologies for product lifecycle management.

Seipee is investing in process digitalization to reduce time-to-market and increase responsiveness to customer needs.

The next industrial revolution will not be made of indistinct automatons, but of intelligent, modular solutions perfectly tailored to the real needs of industry.