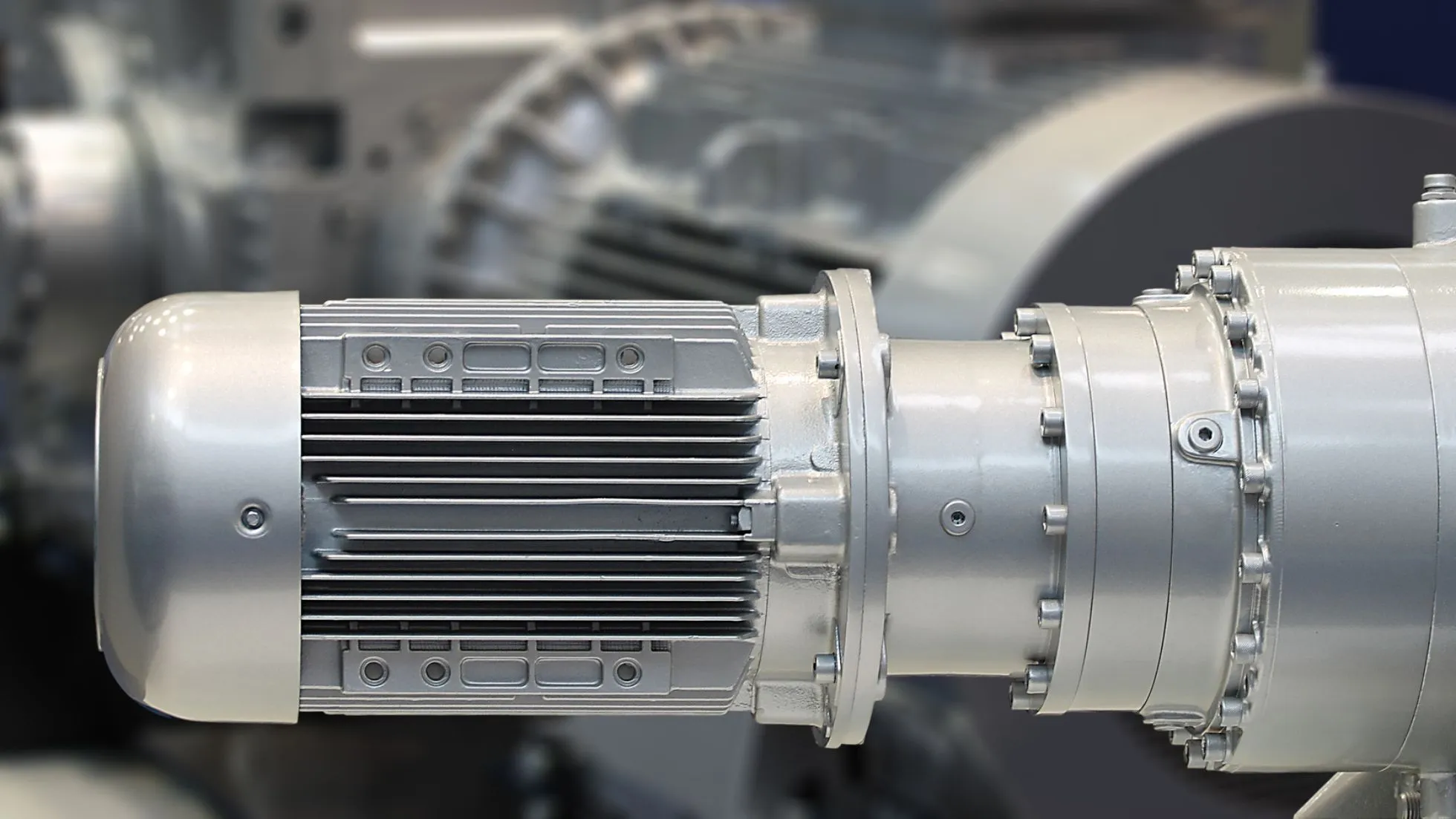

In the era of industrial digitalization, even the purchase of an electric motor is radically changing. Technical data becomes a decision-making element, online configurators replace paper datasheets, and intelligent platforms allow designing and ordering custom solutions with just a few clicks.

The Digital Evolution of the Industrial Purchasing Process

Until a few years ago, buying an electric motor required manual interactions, long waits, and comparisons using paper catalogs.

Today, the industrial world expects immediate responses, accuracy, and traceability.

Digital configurators allow you to select size, voltage, protection class, flanges, accessories, and even mechanical or electrical customizations, receiving datasheets, 3D models, and quotes in real time.

Digitalization starts from data quality.

An intelligent configurator only works if the technical database is consistent, updated, and structured.

Seipee has invested in standardizing technical data, digitizing components, and centralized variant management.

This enables generating reliable configurations, compatible with the customer’s CAD systems, and immediately integrable into internal processes.

A digital system drastically reduces the margin of error: guided selection prevents incompatible combinations, automatic code generation speeds up production, and the customer receives exactly what they selected.

This improves purchasing process efficiency, reduces response times, and allows Seipee to be more responsive even in dynamic markets where time-to-market is a competitive factor.

Industrial Intelligence Applied to B2B

In the B2B sector, the customer-supplier relationship is evolving: you no longer just buy a product, but a digital experience.

Seipee has developed customer-dedicated portals where you can access order history, download certificates, check delivery status, download 2D/3D drawings, and contact technical support instantly.

This transforms sales into an ecosystem of value-added after-sales services.

Configurator design is not just a technical matter but also a user experience issue.

A clear, intuitive, and adaptive interface allows even non-expert users to complete a complex configuration.

Experienced technicians can access advanced features such as STEP export, compatibility with CAD environments, or creation of parametric libraries.

Seipee works to offer a professional yet user-friendly interface.

For structured customers, digitalization goes further: APIs (Application Programming Interfaces) enable direct integration of the catalog and configuration functions within the customer’s ERP, PLM, or purchasing software.

This means eliminating manual steps, generating automatic orders, speeding up design, and maintaining consistency between purchasing and mechanical design.

A true evolution in the industrial approach to procurement.

Towards a Fully Digitalized Industrial Supply Chain

With system integration and real-time data collection, enabling predictive purchasing features becomes possible: scheduled orders based on estimated wear, automatic suggestions based on purchase history, automatic reorder of recurring parts.

This reduces downtime, optimizes inventory, and makes the supply chain smoother and more efficient.

Every motor configured online can become a digital twin, an exact digital copy of the physical product.

Seipee is working on offering, beyond the classic datasheet, interactive documentation updated in real time, also useful during maintenance, overhaul, or revamping.

The digital twin enables more advanced product lifecycle management.

Digitalizing the purchasing process does not only mean simplifying: it also means guaranteeing data security, operational continuity, and future adaptability.

Seipee relies on scalable cloud platforms, with automatic backups, activity tracking, and restricted access for authorized customers.

This ensures reliability, continuity, and room for evolution over time. Customers can therefore count on a stable, fast, and future-ready infrastructure.