This article explores how the synergy between high-efficiency electric motors and intelligent technologies is transforming industrial production, generating savings, performance, and sustainability.

Energy Efficiency as a Pillar of Industrial Competitiveness

Electric motors account for about 70% of energy consumption in the industrial sector.

Investing in high-efficiency motors means drastically reducing operating costs in the medium to long term.

IE3 and IE4 motors (and now also IE5), although with a slightly higher initial investment, offer a concrete economic return thanks to reduced consumption, longer durability, and lower maintenance needs.

Replacing obsolete motors is one of the most effective actions to improve the energy efficiency of a production plant.

At the European level, the Ecodesign Directive has imposed minimum efficiency requirements for electric motors placed on the market, pushing companies to renew their machinery.

In Italy, tools like the Transition Plan 5.0, Tax Credits for investments in capital goods, and incentives for energy savings are making the adoption of high-efficiency technological solutions increasingly advantageous.

Seipee, in this context, supports customers also in selecting compliant and incentivized solutions.

Energy efficiency means designing the system as a whole: choosing a correctly sized motor, integrating it with an inverter, reducing mechanical losses, ensuring adequate ventilation and maintenance.

The work starts with analyzing the operating conditions: overloads, frequent starts, intermittent cycles.

Thanks to its experience, Seipee supports companies in designing integrated and optimized systems, avoiding waste and increasing overall energy yield.

Integration with Industrial Automation

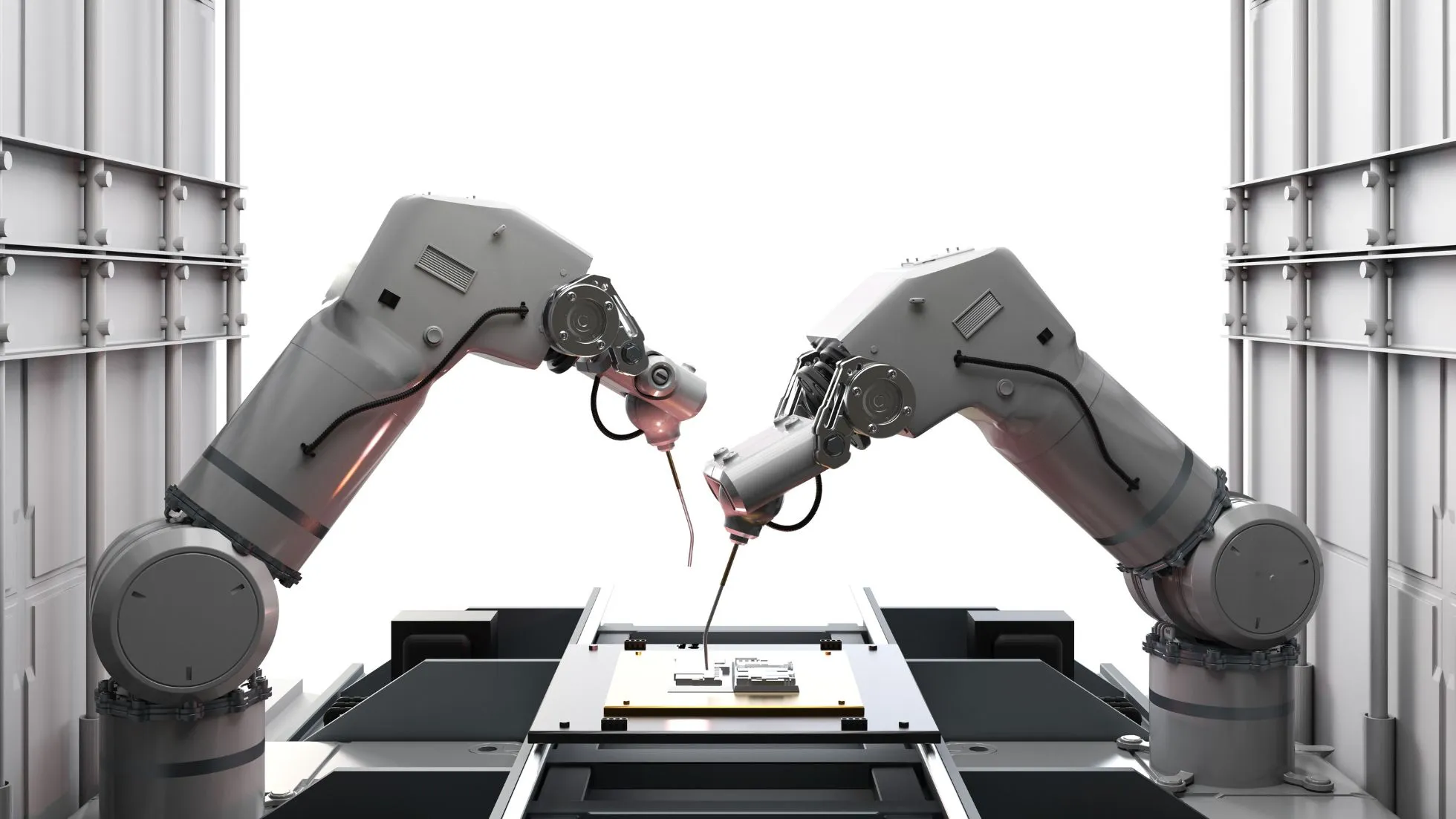

The integration between electric motors and automation systems is the foundation of the smart factory.

Seipee motors can be equipped with encoders, vibration and temperature sensors, digital interfaces, and readiness for predictive monitoring.

These devices allow collecting real-time data, detecting anomalies, optimizing production cycles, and preventing failures, reducing machine downtime and improving productivity.

To be effective, motors must communicate.

Interfaces with fieldbuses (such as Modbus, EtherCAT, Profinet, CANopen) allow motors to interact with PLCs, HMIs, and MES software.

This data exchange is fundamental to synchronize production lines, adjust speeds according to demand, perform predictive maintenance, and adapt processes based on operational parameters.

Automation today is data-driven, and motors are one of its main information sources.

Thanks to automation, it is possible to manage complex production lines with greater flexibility.

Electric motors can be controlled by inverters that modulate torque, speed, and acceleration in real-time, adapting to the type of material, load, and environmental conditions.

This means less waste, higher product quality, and the ability to reconfigure production quickly. In highly variable scenarios like today’s, this capability makes the difference.

Efficiency and Automation for a Sustainable Industry

The adoption of high-efficiency motors and automation systems significantly contributes to reducing the industry’s ecological footprint.

An optimized plant consumes less energy, produces less waste, and requires fewer corrective interventions.

This has a direct impact on CO₂ emissions, pollution, and economic sustainability.

Companies investing in these technologies also position themselves more solidly from a reputational and regulatory perspective.

Investments in efficient and automated technologies fully fall under ESG (Environmental, Social, Governance) criteria.

Seipee supports clients in choosing solutions that back environmental sustainability goals as well as operational safety and technical governance.

Companies documenting their ESG path are rewarded by customers, partners, and investors.

Technology in this scenario becomes a strategic tool.

The future of industry is 5.0: a synergistic collaboration between man, machine, and the energy system.

Electric motors are no longer passive elements, but active components of an interconnected ecosystem.

Thanks to automation and data collection, they become protagonists of a more human, sustainable, and efficient production process.

With its experience and ability to design custom solutions, Seipee positions itself as the ideal partner in the transition to this new industrial vision.